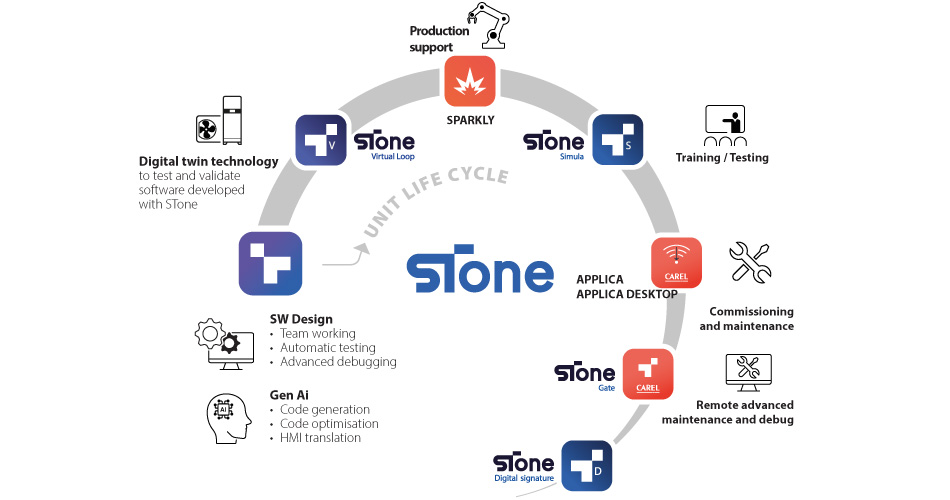

STone Virtual Loop - Advanced emulation for HVAC/R software development

In an increasingly dynamic and competitive industrial scenario, technological innovation is essential for success. Companies that know how to evolve quickly and adopt the latest tools are able to stand out on the market and achieve greater success. Within this context, STone Virtual Loop represents a strategic resource to best support unit manufacturers for faster and more precise application development, offering concrete benefits specifically in the HVAC/R business.

A thermodynamic assistant at your side at all times

A thermodynamic assistant at your side at all times

STone Virtual Loop is CAREL’s advanced emulator that virtualises physical models of working thermodynamic units, replicating their behaviour and interactions in a digital environment, using digital twin technology. It can be used to validate software for units such as residential heat pumps, commercial chillers/HP and air conditioner, without requiring actual working units.

The tool integrates natively into STone, the perfect partner for advanced programming that is revolutionising the software development process. STone Virtual Loop further enhances the benefits of the STone ecosystem, by offering a realistic yet virtual emulation environment for testing and validating software, reducing the need for physical hardware or dedicated labs. This approach allows continuous quality improvement, optimising time, resources, and results.

Main benefits

STone Virtual Loop helps achieve numerous operational and strategic benefits.

Faster time to market: Logic and user interfaces can be tested in real time in a safe simulated environment. Any issues or inefficiencies can be identified and corrected before field deployment accelerating the development cycle and reducing the risk of errors and malfunctions.

Faster time to market: Logic and user interfaces can be tested in real time in a safe simulated environment. Any issues or inefficiencies can be identified and corrected before field deployment accelerating the development cycle and reducing the risk of errors and malfunctions.

Flexibility and agile development: Any changes can be implemented, tested and validated iteratively, in line with agile development methods.

Flexibility and agile development: Any changes can be implemented, tested and validated iteratively, in line with agile development methods.

Cost optimisation: by reducing the need for physical laboratories and prototypes allows a significant reduction in operating costs and validation tests, both for new unit designs and the required routine maintenance on the current unit portfolio.

Cost optimisation: by reducing the need for physical laboratories and prototypes allows a significant reduction in operating costs and validation tests, both for new unit designs and the required routine maintenance on the current unit portfolio.

Simplified learning and onboarding: Real-time display of system operation and changes in values makes STone Virtual Loop an effective learning tool for developers, even those with less thermodynamic expertise. It also makes it easier and faster for new members to join and align with the work group.

Simplified learning and onboarding: Real-time display of system operation and changes in values makes STone Virtual Loop an effective learning tool for developers, even those with less thermodynamic expertise. It also makes it easier and faster for new members to join and align with the work group.

Immediate support for personnel in the field: Quickly check for any malfunctions due to incorrect configurations applied to the unit in the field. By sending unit configurations to specialist support personnel, any interruptions to service are minimised.

Immediate support for personnel in the field: Quickly check for any malfunctions due to incorrect configurations applied to the unit in the field. By sending unit configurations to specialist support personnel, any interruptions to service are minimised.

Integration and operational simplicity

STone Virtual Loop is fully compatible with CAREL’s physical (c.pco, pYc, ...) and virtual (STone Simula) electronic controllers.

STone Virtual Loop generates physical outputs based on advanced mathematical models, while intuitive operation means the results are available in just a few simple steps. Once the unit model to be emulated has been selected from those available (residential heat pumps, commercial chillers/HP and air conditioner), the parameters are entered, the values are mapped, and the initial and boundary conditions are defined. The controller receives the values as inputs, the software processes the response, managing the actuators according to the control logic; STone Virtual Loop then dynamically updates the system parameters so as to create a continuous simulation loop.

A competitive advantage in the digital age

This approach revolutionises one of the critical stages in the development of new units for manufacturers. By testing and optimising the software applications safely and efficiently, development time and costs are slashed, while at the same time improving the reliability and performance of the solutions.

Click here for more details about STone Download the brochure